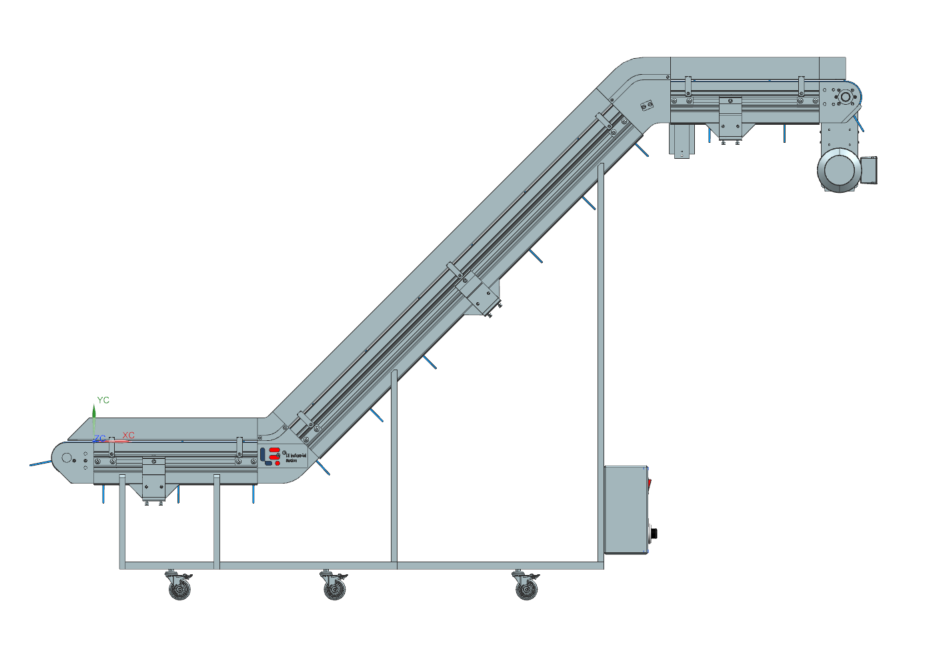

Description

The name “Z-type” refers to the distinctive Z-shaped configuration of the conveyor, which resembles the letter “Z” when viewed from the side. This configuration allows the conveyor to change the direction of material flow both vertically and horizontally, making it an efficient solution for applications with limited floor space or when a change in elevation is required.

-Type conveyors offer several advantages in material handling applications:

- Space optimization: The Z-shaped configuration allows for vertical movement, making it an ideal solution for facilities with limited floor space. It enables efficient use of vertical space by transporting items between different levels.

- Flexibility: Z-type conveyors can be customized to accommodate various product sizes, weights, and shapes. They can handle delicate or fragile items without causing damage during transportation.

- Gentle handling: The inclined sections of the conveyor are designed to minimize product damage or spillage, ensuring gentle and controlled handling of the items.

- Improved productivity: Z-type conveyors can streamline material flow by eliminating the need for manual lifting or transfer between different elevations. This helps to increase overall productivity and reduce labor requirements.

- Hygienic design: Z-type conveyors used in food processing or pharmaceutical industries are often designed with sanitary features, such as easy-to-clean materials and smooth surfaces, to meet hygiene standards.

In summary, Z-type conveyors are specialized conveyor systems that enable vertical or inclined transportation of materials or products. Their unique configuration offers space-saving advantages and facilitates efficient movement between different levels or processes, making them valuable assets in various industrial applications.